Recognizing the Specifications for Welding Inspection Gilbert Arizona: A Total Overview

Recognizing the Specifications for Welding Inspection Gilbert Arizona: A Total Overview

Blog Article

Welding Evaluation Demystified: Trick Procedures, Tools, and the Necessary Role They Play in Maintaining High-Quality Welds

Welding evaluation serves as a critical foundation in the assurance of structural stability and top quality in bonded joints, impacting different markets from building to production. What are the vital processes and tools that make sure these standards are supported?

Relevance of Welding Evaluation

Making sure the integrity of bonded joints is paramount in numerous sectors, making the value of welding evaluation obvious. The quality of welds directly affects the safety and security, efficiency, and long life of structures and parts. In industries such as construction, vehicle, aerospace, and manufacturing, any type of failing in bonded joints can lead to tragic repercussions, including structural failings, tools malfunction, and death.

Welding assessment offers as an essential quality assurance measure, guaranteeing that welds meet defined criteria and governing demands. It recognizes flaws such as cracks, porosity, and insufficient combination that may jeopardize the strength of the weld. By discovering these concerns early, welding examination can stop expensive rework, hold-ups, and potential safety hazards.

Furthermore, welding inspection promotes compliance with industry criteria and accreditations, enhancing the reputation of organizations and their items. It additionally supports constant improvement by providing beneficial feedback to welding employees, allowing them to improve their strategies and procedures.

Ultimately, the relevance of welding examination can not be overstated; it is necessary for keeping premium welds, ensuring safety and security, and safeguarding investments throughout numerous sectors.

Trick Assessment Processes

Efficient welding assessment counts on a series of crucial procedures developed to examine the top quality and integrity of welds. These procedures include both non-destructive and visual screening (NDT) methods, guaranteeing that any problems are identified prior to they compromise structural stability.

The primary step in the examination process is a detailed visual assessment, which enables examiners to evaluate welds for surface defects such as cracks, undercuts, and incomplete blend. Adhering to aesthetic checks, various NDT strategies may be utilized, consisting of ultrasonic screening, magnetic particle screening, and radiographic screening. Each technique uses special advantages; for instance, ultrasonic screening can spot inner imperfections, while radiographic testing provides an irreversible document of the weld's interior framework.

Additionally, it is vital to verify conformity with appropriate codes and standards, making certain that the weld meets industry requirements. This includes inspecting weld measurements and positioning, as inappropriate dimensions can result in failings under lots.

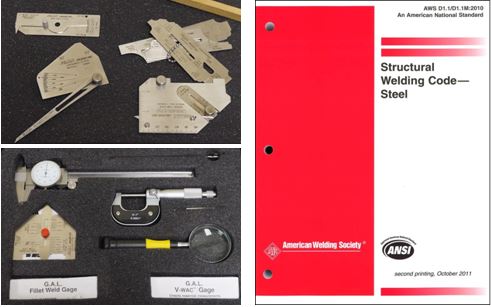

Vital Devices for Assessment

Frequently using the right tools is vital for achieving exact welding evaluations. A comprehensive collection of assessment tools assists make sure that welds satisfy strict high quality requirements and specifications.

Among the primary devices is the visual inspection scale, which permits inspectors to analyze surface area More about the author problems, such as tidiness and surface area coating, straight. Additionally, calipers and micrometers are essential for gauging weld measurements and guaranteeing they adhere to required resistances.

For more comprehensive assessments, ultrasonic screening (UT) tools is indispensable. This technique uses high-frequency acoustic waves to spot interior problems and analyze product thickness. Magnetic fragment screening (MT) and color penetrant testing (PT) are essential for recognizing surface and near-surface flaws, offering immediate visual indications of prospective problems.

Welders should additionally be equipped with firmness testers, which assess the mechanical residential properties of the weld metal and base materials, ensuring they satisfy given requirements. Lastly, documenting findings with digital inspection tools boosts traceability and high quality control. By employing these necessary tools, assessors can maintain premium welds, eventually adding to the safety and dependability of bonded frameworks.

Typical Problems and Their Detection

Welds, comparable to the foundation of structural stability in building and construction and production, can display various defects that jeopardize their efficiency and security. Typical problems include porosity, fractures, undercut, absence of blend, and slag additions (Welding Inspection Gilbert Arizona). Each of these defects can manifest due to incorrect welding techniques, inadequate product option, or insufficient preparation

Detection of these problems can be achieved via various non-destructive testing techniques, consisting of visual evaluation, ultrasonic testing, and radiographic screening. Each technique plays a vital duty in recognizing these faults, guaranteeing that the stability of the weld is maintained and lowering the risk of failure in critical applications.

Finest Practices for High Quality Assurance

Ensuring the best of welds is critical for architectural stability and safety, particularly in markets where the consequences of failing can be serious. To attain this, several best methods for quality assurance must be implemented throughout the welding procedure.

First, a robust welding treatment specification (WPS) must be established, describing the required parameters for every welding procedure. This makes certain consistency and adherence to industry standards. Second, extensive training and certification of welders are necessary; experienced workers are much better furnished to produce top quality welds and recognize prospective problems.

Routine inspections Bonuses ought to be incorporated into the welding process, utilizing both aesthetic and non-destructive screening (NDT) approaches to discover problems early on. Routine calibration of evaluation devices is essential to maintain precision. Furthermore, my sources recording all welding activities, including assessments and rehabilitative actions, produces a deducible document that can be very useful for quality assurance.

Final Thought

To conclude, welding examination functions as a crucial system for making sure the honesty and reliability of welded joints across sectors - Welding Inspection Gilbert Arizona. With the implementation of essential assessment processes and the use of vital tools, companies can effectively determine and address possible issues. Adherence to ideal practices in quality control not only enhances security but also makes certain conformity with industry requirements, ultimately contributing to the longevity and performance of frameworks and elements

Welding assessment offers as a critical backbone in the guarantee of structural integrity and top quality in bonded joints, impacting different sectors from building to manufacturing.Making sure the stability of bonded joints is extremely important in different sectors, making the relevance of welding examination obvious.Welding examination offers as a critical high quality control step, making certain that welds satisfy specified requirements and regulative needs. By employing these essential devices, inspectors can maintain premium welds, ultimately adding to the safety and dependability of welded frameworks.

In conclusion, welding examination serves as a crucial mechanism for making sure the stability and dependability of welded joints throughout sectors.

Report this page